Even if you've been sewing for awhile and feel quite comfortable with your sewing machine, I'm sure there are still parts of your machine that you don't quite understand. I'm pretty comfortable experimenting, but sometimes, even I, have that nagging voice in the back of my head that says, "If I fool with that, the whole machine might implode on itself." Luckily for me, that's never happened. My machine is still in one piece and running great even after all these years of pushing buttons and turning knobs even when I'm not quite sure of the result. This is why it's great to check out your sewing machine manual, because you really get to see what makes the machine work.

Even if you've been sewing for awhile and feel quite comfortable with your sewing machine, I'm sure there are still parts of your machine that you don't quite understand. I'm pretty comfortable experimenting, but sometimes, even I, have that nagging voice in the back of my head that says, "If I fool with that, the whole machine might implode on itself." Luckily for me, that's never happened. My machine is still in one piece and running great even after all these years of pushing buttons and turning knobs even when I'm not quite sure of the result. This is why it's great to check out your sewing machine manual, because you really get to see what makes the machine work.

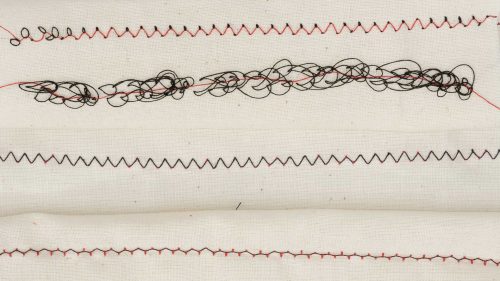

For a lot of us, one part of the machine that seems to always be a mystery is thread tension. Like that sewing machine manual, it sounds a lot scarier than it is. I know you're probably like me and willing to leave well enough alone, but if you've ever had problems getting your stitches to look right on that new fabric, thread tension may very well be the key.

So now you're asking, "Ok, so what exactly is thread tension and how do I use it?" Well, fortunately for you, that's the focus of this week's video tutorial. I will give you a hint. Different types of fabric, do require different thread tensions and also the type of thread you use can also affect it. We tackle upper thread tension and lower thread tension. So if you plan on experimenting outside of cotton, it's good to at least have this information on hand. Experiment away!

Thanks i just started out, your tutorials are amazing now i know how to adjust tension.

My sewing machine recommends a 6 and I think it really depends as some denim are thicker than others. I would start there and adjust if necessary.

what tension setting do you recommend for sewing denim?

Thanks for this info, i’m new to sewing so this will help me.

OMG! Fixed it!

Thanks so much for this video! I haven’t been sewing and contemplating buying a new machine. Hopefully, I can fix the problem now that I have seen this. My thread tension is just all wrong!! Wish me luck!

omg, I’m so sorry. I never received a notification for this question and I just saw this. The first thing I would check is make sure you have everything threaded correctly with both the top spool and also the bobbin. If everything is threaded right, look at your bobbin thread. The thread should be wound on the bobbin evenly and look neat and organized. Also, if you have two dials on your machine, one of them might be related to the presser foot. Just consult your sewing machine manual and make sure you’re using the right dial for making your adjustment. If, after all that, you’re still having issues, then I think you better take the machine to a repair shop. It’s definitely not normal to have a thread tension dial at zero.

My sewing machine tension is set at 0 and is still way too tight. Is there anything that I can do without having to have it repaired? Thank you